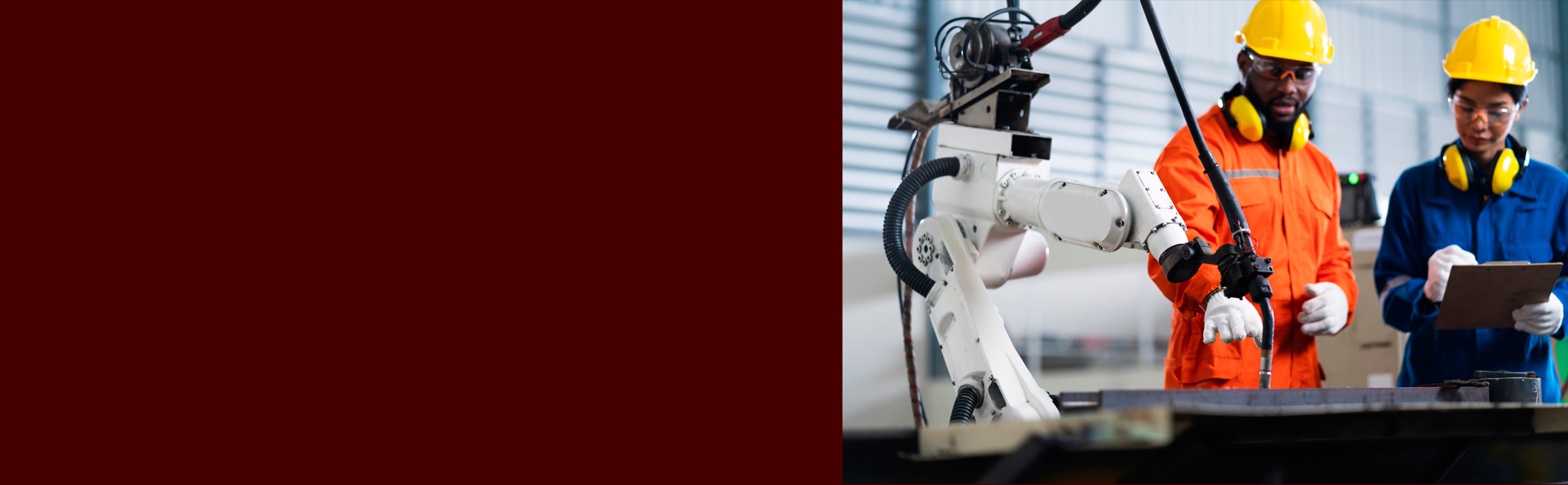

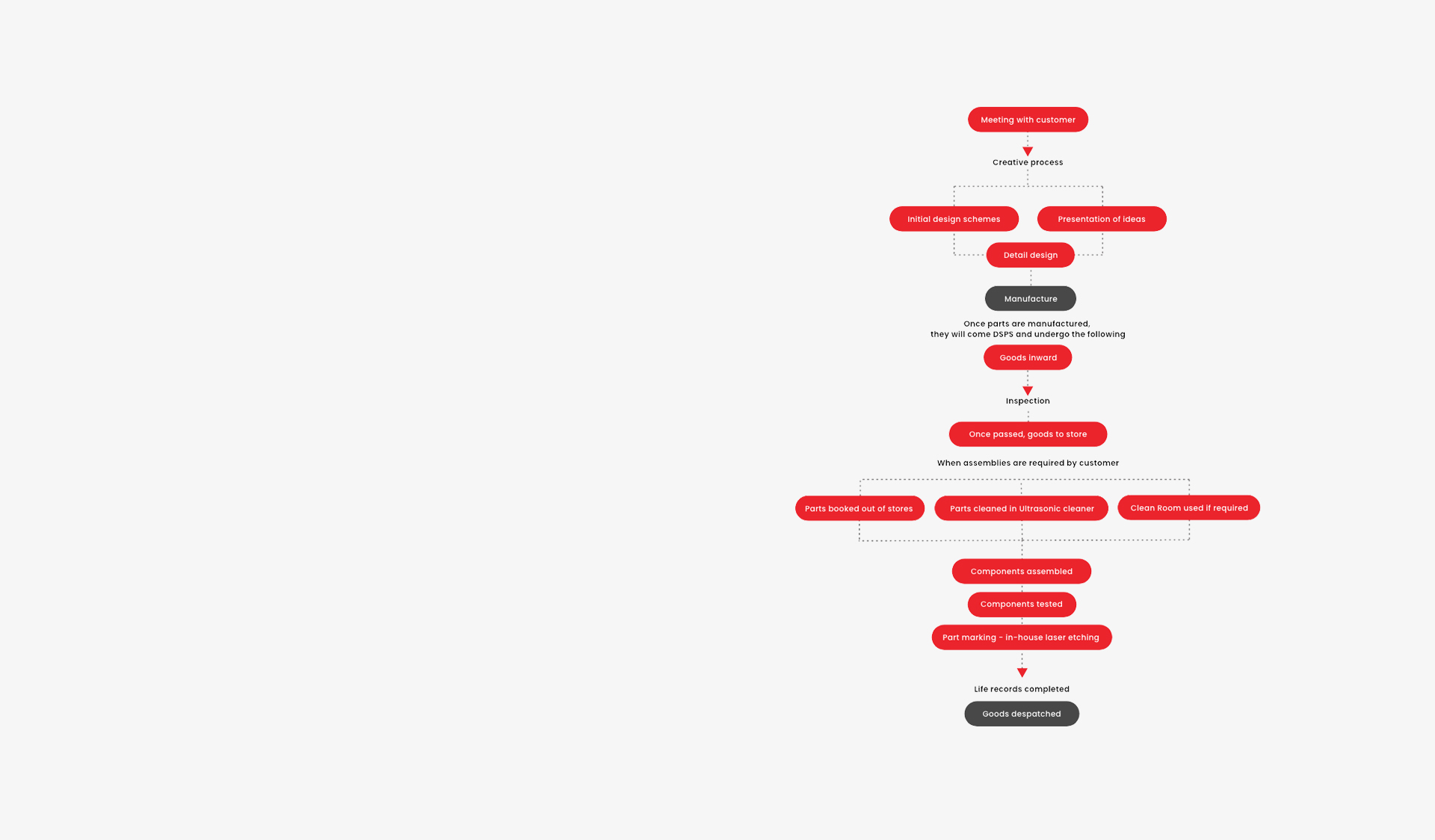

DSPS Engineering specialises in crafting customised high-tech engine components and assemblies for clients operating in challenging environments near performance limits. Our company employs a "zero defects" total quality management process, ensuring traceability from raw materials to obsolescence.

Parts are meticulously managed, guaranteeing design conformance throughout their global service life and under specified conditions. We firmly believe in the binary approach to task execution: it's either done correctly or incorrectly.