In motorsport, every component must be crafted to perfection, and here at DSPS, we take pride in our commitment to precision and performance. In this blog post, we invite you to glimpse behind the scenes into our meticulous manufacturing process for wastegates and ALS (anti-lag system) valves. Discover how we create genuinely race-ready components from design to assembly and testing.

Design for performance and manufacture

The journey to crafting high-performance wastegates and ALS valves begins with a rigorous design process. At DSPS, our engineers are focused on achieving the perfect blend of performance and manufacturability. We strive to design components that meet the exacting demands of motorsport and are also practical to manufacture with precision.

Quality control at every step

Quality is paramount in the motorsport industry. That's why all inspection of parts is done in-house at DSPS. Our dedicated team of quality control experts meticulously examines every component to ensure it meets our stringent standards. We have our own in-house Total Quality Management (TQM) system, commensurate with modern Aerospace standards. This hands-on approach allows us to maintain complete control over the quality of our products.

Batch numbering - Traceability at its core

Traceability is a cornerstone of our manufacturing process. Each part is assigned a unique batch number, enabling us to track its journey from production to the racetrack. This batch numbering system ensures we can trace and monitor every component throughout its lifecycle. The traceability from when the metal is manufactured allows a complete history of every part. In the unlikely event of a part failure, we can then monitor other parts with similar batch numbers to make sure there are no problems.

Picking of component parts

We follow a systematic process to create our wastegates and ALS valves. Route cards are employed, listing all relevant batch numbers and specifications. Additionally, a life number is assigned to each assembly, ensuring that we maintain detailed records of its service history and use.

Cleaning before assembly

Before assembly, each component undergoes thorough cleaning to ensure no contamination could compromise performance. All our parts are ultrasonically cleaned, using a cleaning solution that doesn’t compromise the metallurgy of the components, thus not affecting fatigue life in any way. This meticulous step guarantees that our wastegates and ALS valves are assembled with pristine components.

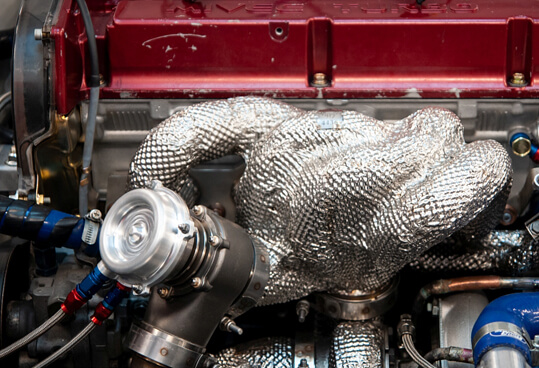

Precise assembly

Assembling our wastegates and ALS valves is an art of precision. Our skilled technicians follow rigorous procedures to create components that are not only high-performing but also dependable under the most challenging conditions. This step is where our design for manufacturability truly shines.

Proving performance with rigorous testing

Before any DSPS component leaves our facility, it undergoes rigorous testing. Parts can be pressure and flow tested, as well as electronically tested where sensors are concerned. We ensure that each wastegate and ALS valve meets our performance criteria, ensuring they are ready to tackle the demands of motorsport. Only those that pass with flying colours move on to the next stage.

Life number etched onto assembly

Each assembly is etched with a life number to add a final layer of traceability. This unique identifier allows us to monitor the component's performance throughout its lifetime, enabling us to track and improve its performance over time.

The finish line

The last step in our manufacturing process is the sign-off. Once a wastegate or ALS valve has passed all inspections and testing, it is officially deemed ready for the racetrack. It's a moment that represents the culmination of our dedication to precision and performance.

In conclusion, the manufacturing process for wastegates and ALS valves at DSPS is marked by precision, quality control, and a commitment to performance. From the design phase to final sign-off, we leave no stone unturned in our quest to produce components that are not just race-ready but also designed to excel in motorsport. Enquire with DSPS for engine components that are engineered with precision and a passion for performance.