In the thrilling world of motorsport engineering, where every fraction of a second counts, components like wastegates play a crucial role in achieving peak performance and safeguarding the engine. At DSPS, we understand the significance of these intricate devices, and here, we'll demystify wastegates, explaining how they work and why they matter in high-speed racing.

What is a wastegate?

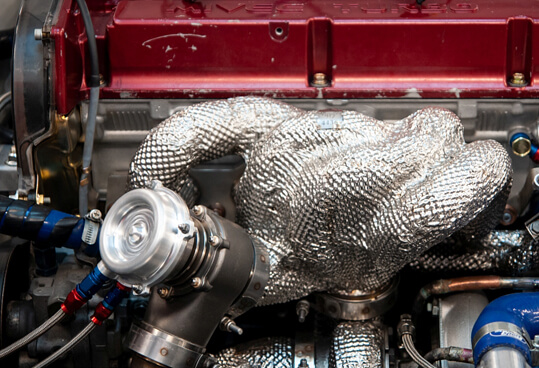

A wastegate is a valve that controls the flow of exhaust gases to the turbine wheel in a turbocharged engine system. It is used to regulate the boost pressure produced by the turbocharger.

When the engine is running, exhaust gases flow through the turbine wheel, spinning it and forcing air into the engine's inlet system. As the engine speed increases, the exhaust gas flow increases, and the turbine wheel spins faster. However, too much boost pressure can damage the engine, so the wastegate is used to limit the amount of boost pressure produced by the turbocharger.

The wastegate is typically controlled by a pressure actuator connected to the wastegate. When the boost pressure reaches a certain level, the pressure actuator opens the wastegate, allowing some of the exhaust gases to bypass the turbine wheel. This reduces the speed of the turbine wheel and limits the amount of boost pressure produced by the turbocharger.

Wastegates can be either internal or external. Internal wastegates are built into the turbocharger housing, while external wastegates are mounted separately. External wastegates are more common on high-performance turbocharged engines, offering more flexibility and control.

How do wastegates work?

Turbochargers are employed to force-feed air into the engine's combustion chambers, enhancing power and performance. However, there's a delicate balance to be maintained when it comes to this boost pressure. Too much boost, akin to an engine on overdrive, can lead to a cascade of undesirable consequences.

Wastegates play a crucial role in protecting the engine from over-boost. When the turbocharger generates excess pressure, the wastegate opens, diverting some exhaust gases away from the turbine wheel. This, in turn, reduces the turbo's power and prevents the engine from receiving an excessive boost that it cannot handle. Boost levels can range from 1 Bar to 5 Bar – it depends on the application.

Over-boost can put immense strain on both the turbocharger and the engine itself. The turbocharger may experience excessive heat, wear, and damage, while the engine can be pushed beyond its design limits, risking catastrophic failure. Over-boost protection is paramount in the high-stakes world of motorsport, where engines operate at the edge of their performance envelope.

Why do wastegate’s matter?

While wastegates are primarily about protecting the engine, they also offer a unique advantage in maximising performance. By precisely controlling the wastegate, engineers can operate the engine closer to its boost limit without crossing the danger threshold. This fine-tuning allows for consistent, high-performance operation.

Wastegate control allows engineers to dial in the perfect amount of boost for each situation. Whether for acceleration out of a tight corner or top speed on a straightaway, the ability to manage boost pressure with precision can make all the difference on the racetrack. It's all about achieving that delicate balance between raw power and engine reliability.

In conclusion, the wastegate's role as a pressure relief valve is fundamental in motorsport engineering. By carefully controlling and moderating the boost pressure, it safeguards the engine's integrity, preventing potential damage to both the turbocharger and the engine itself. This simple yet crucial function is the key to balancing the pursuit of power with the imperative of reliability in the world of high-performance motorsport.

At DSPS, we understand the importance of these intricate devices and use our expertise to ensure that they work flawlessly in pursuit of victory. If you need top-tier motorsport engineering solutions, look no further than DSPS – where innovation meets precision.