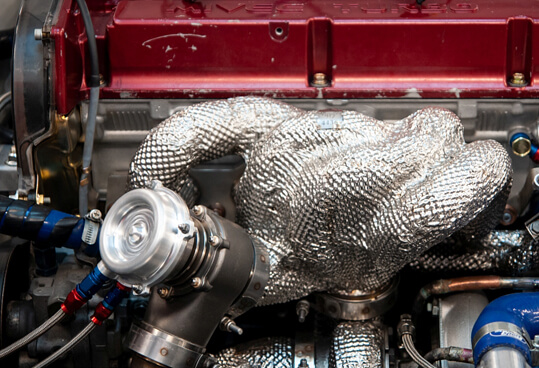

Finding the perfect balance between power and reliability is paramount in high-performance motorsport. To finish first, first you have to finish. At DSPS, we understand that choosing the right wastegate and ALS (anti-lag system) valve is a decision that can make or break a race. Here, we'll delve into the art of making this crucial choice, exploring the factors that help you select the ideal components for your engine, from engine capacity to valve control methods.

Know your engine

Choosing the right wastegate (WG) or ALS valve begins with thoroughly understanding your engine and control philosophy. Several vital parameters should be considered:

Engine capacity

The size and capacity of your engine play a significant role in determining the type and size of wastegate and ALS valve you need. Larger engines may require more substantial components to handle the increased demands, while smaller engines may benefit from more compact options. It’s more a question of power and boost, which lead us to the points below.

Power level

Your engine's desired power output is crucial in selecting the right wastegate and ALS valve. Components must be capable of managing the boost pressure needed to achieve your power goals while maintaining reliability.

Boost level

The desired boost pressure is a fundamental consideration. Wastegates and ALS valves must be able to withstand and manage boost pressure effectively. Too much or too little boost can significantly impact engine performance and wastegate/ALS longevity.

Valve control method

The choice of valve control method is an essential decision in finding the right wastegate and ALS valve. Different control methods offer varying degrees of precision and adjustability:

Pneumatic control

Pneumatic control is a traditional method that relies on air pressure to regulate the wastegate and ALS valve. It provides a straightforward and reliable approach, with the valves being open or closed.

Solenoid control

Solenoid control is known for its quick and precise adjustments. It offers a high level of control over boost pressure and is often used in sophisticated engine management systems. The main advantage of solenoid control is reduced compliance within the system, hence faster response.

Position control

Position control uses an electronic actuator to adjust the valve's position precisely. This method offers fine-grained control and is commonly found in advanced motorsport setups, often with hydraulic control as well.

Relief valve or boost optimisation

The final piece of the puzzle is to determine your primary objective with the wastegate and ALS valve:

Pressure relief valve

To protect your engine from over-boost, you'll want to use the wastegate primarily as a pressure relief valve. This ensures that excess boost pressure is diverted, preventing damage to your turbocharger and engine.

Boost optimisation

On the other hand, if you aim to maximise performance by optimising boost pressure, your wastegate and ALS valve become precision instruments in controlling and fine-tuning the boost levels. This approach allows you to operate your engine closer to its boost limit, unlocking higher performance while maintaining reliability.

In conclusion, balancing power and reliability in motorsport engineering begins with selecting the right wastegate and ALS valve. Consider your engine's capacity, power level, and desired boost pressure to make this crucial choice. Factor in the valve control method that best suits your needs and defines your objective, whether it's pressure relief or boost optimisation. By mastering this balance, you can enhance your engine's performance and reliability, ensuring success on the racetrack.

Trust DSPS to provide the expertise and components you need for the perfect racing formula. Get in touch with our team today to find out more.