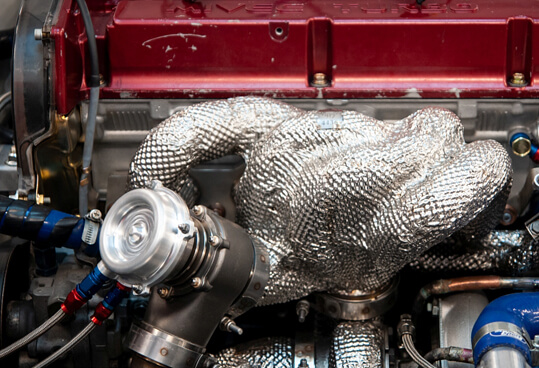

Every decision and detail counts when striving for that extra edge on the racetrack. At DSPS, we understand that the right materials and design choices can make all the difference in the performance of our wastegates. Here, we spotlight the crucial role of materials and design in creating high-performance wastegates tailored to the unique demands of motorsport.

Choosing the best material

The choice of material for motorsport components is a vital consideration. In the case of wastegates, the material selected must satisfy the regulations specific to the motorsport category in which they will be used (for example, some categories don’t allow the use of Titanium components, on grounds of cost). At DSPS, we understand the importance of adhering to these regulations, ensuring that our components meet the standards set by motorsport authorities.

Lighter, stiffer, stronger

In the quest for peak performance, the materials used in motorsport engineering must consistently push the boundaries of what's possible. Wastegates are no exception. We are committed to creating lighter, stiffer, and stronger wastegates. These qualities are essential to maximising power and efficiency while maintaining the durability needed to withstand the rigours of high-speed racing.

WG valves

- Nimonic 80: Known for its high-temperature strength and corrosion resistance.

- Inconel 625: Offers exceptional strength and resistance to oxidation and corrosion.

- Inconel 718: Renowned for its impressive tensile strength and heat resistance.

ALS valves

- Stainless Steel: Combines corrosion resistance with strength, making it ideal for specific applications.

- Inconel: Provides superior strength and resistance to extreme temperatures and stress.

Castings

- Inconel 625 is a trusted choice for our castings in motorsport wastegates. It is favoured for its excellent corrosion resistance, high-temperature strength, and suitability for precision casting processes. Some manufacturers use Stainless Steel for their castings, however at DSPS, we use Inconel 625 to ensure the reliability and performance of our wastegates at extreme operating conditions.

Valve guide material

The choice of valve guide material is critical to the functionality of wastegates. Federal Mogul sintered material and Colsibro are carefully selected for their durability and resistance to wear and tear. This ensures that the valves operate smoothly and consistently under demanding racing conditions.

Diaphragms

At DSPS, we take diaphragms to the next level. Our custom-made diaphragms use high-temperature elastomer, reinforced with nomex core, ensuring they can withstand motorsport applications' intense heat and pressure. These diaphragms are designed with precision to maintain performance when it matters most.

Studs and nuts

DSPS utilises aerospace-grade custom studs and nuts in our wastegate assemblies to guarantee the utmost reliability and safety. These components are specifically chosen for their strength, precision, and resistance to extreme conditions.

In conclusion, materials and design in motorsport wastegates are not to be underestimated. DSPS is committed to pushing the boundaries, adhering to regulations, and using the best materials available to craft wastegates that deliver peak performance, durability, and reliability. Whether it's the choice of valve materials, castings, or diaphragms, we take each decision seriously because every detail can make all the difference in motorsport. Get in touch with DSPS today to discuss your options.